Learn How to Build a Chopper

HOW TO BUILD A CHOPPER WORKSHOP DETAILS

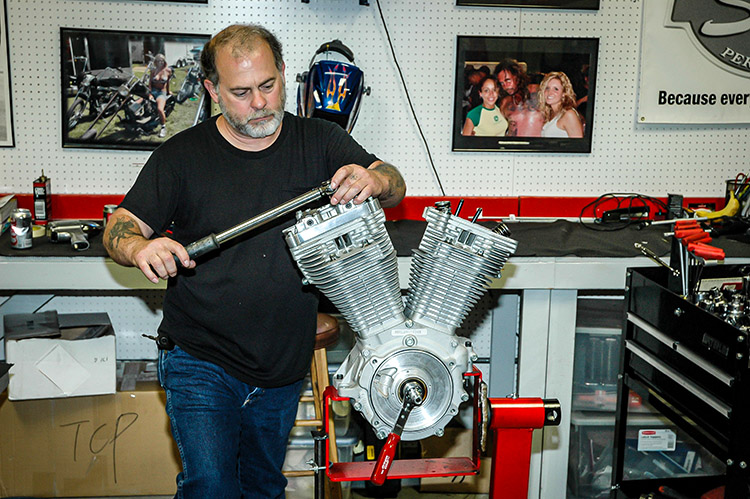

Our intensive and detailed workshops have been developed from the formal training and years of experience we have in bike building and teaching chopper building, engine building and TIG welding.

Redline’s Hands-On Workshops

These hands-on workshops will help you avoid costly mistakes in assembly procedures and in choosing wrong parts for your bike build!

You will also avoid expensive labor rates by learning how to do all the work yourself!

These workshops are basically a highly condensed and well organized “motorcycle mechanics school”. We cover the engine or chopper build part-by-part, and each and every precision micrometer measurement, feeler gauge spec, torque spec, and so on.

Finally, we fire up the engine you build when we start the bike.

Yes, we go slow. It is a lot of work for the teacher to actually cover this much material. These workshops are not filled with lots of coffee breaks and bad jokes. However, the workshops are still a “riot” with the cool personalities that show up! Despite the hard core grinding technical information we cover, the workshops are a blast.

These chopper, engine building and TIG welding workshops are comprehensive “Boot Camps” that will answer ALL of your building questions. You won’t be disappointed with these workshops!

Please Scroll way down TOWARD THE BOTTOM OF THIS PAGE to read the “Engine Building Workshop” description!

Our intensive courses teach you Beginning to Advanced chopper building – all in one workshop. Beginners welcome!

Watch our video to preview our How To Build a Chopper workshops!

Chopper Building Workshop Quick Summary

- How to wire a bike with 3 different detailed and simplified wiring schematics

- Engine & transmission alignment & shimming

- Final drive alignment

- Rake & trail calculations

- Custom electrical wiring

- Fat tire offsets

- Oil line routing of all oil lines

- Wheel spacer fabrication

- Clutch assembly and adjustment

- Use of special tools

- Carburetor setup and tuning, as well as complete tear down and rebuilding

- Brakes install, shimming & bleeding of brake lines

- Assembly of open belt drive primary drive

- Assembly of enclosed chain-driven primary drives

- Advanced motorcycle troubleshooting secrets and engine tuning!

- Troubleshooting electrical and fuel systems.

- Correct start-up procedures that guarantee trouble-free start-up’s every time

- A TIG welding class for day 5 that is optional.

No big classes! Class size is usually anywhere up to 4 students max.

You get a 12 SECTION NOTEBOOK that comes with each workshop. The chopper notebook is packed with hard to get detailed wiring schematics, torque specs, fat tire offsets, rake and trail calculations, wheel and tire specs, special tools, aftermarket parts manufacturers for every part on a bike, parts and tools catalogs and industrial suppliers for bolts and supplies you cannot find anywhere!

There is also a notebook that comes with the engine building workshop that covers all technical specs, service wear limits and overhaul procedures.

These courses are the answer to your problem of getting the REAL information you need about how to build a chopper – instead of a bunch of watered down “how to books” that teach you very little.

Redline Chopper School Workshops

Our build a chopper workshops take you from beginning chopper and engine building to a professional level of knowledge quickly because we teach you how to solve advanced problems!

It would take you years to get this knowledge on the street – if you could even get the knowledge at all!

We give you all of the knowledge and confidence you need to successfully build a chopper, bobber, or a Harley Engine without anxiety or constant fear!

We are dealers for Custom Chrome, Bikers Choice, S&S Cycle, Midwest Motorcycle Supply (Ultima Products), Wire-Plus, Cycle Electric, and MC Advantages.

WE GIVE YOU A HUGE AMOUNT OF KNOWLEDGE IN THIS SEMINAR!

SIGN UP FOR THE WORKSHOPS NOW!!

WE PASS ON TO YOU “THE GOOD STUFF” FROM THE BIGGEST PLAYERS IN THE STOCK BIKE AND AFTERMARKET INDUSTRY: S&S CYCLE AND HARLEY DAVIDSON PHD MATERIALS!!

And we are willing to pass on that technical knowledge to you! We have also had access to the Harley Davidson PHD materials for advanced learning – information we share with you.

Our Specialty is Teaching

We have either been to, or heard about, some of the other chopper building seminars out there.

In most classes, the material was not organized, few technical specs were covered, and their chopper building “war stories” that would teach you valuable lessons had long been “forgotten”. Some classes have good builders, but they do not have in-depth material to teach or good teaching skills.

Unfortunately, some of these classes are mainly just about “bolting a bike together”, and not teaching the critical technical details of motorcycle assembly and motorcycle operating systems…which we do best!

Our classes are small, so that each student gets plenty of “HANDS-ON” experience building a bike and an unobstructed view of the building process.

We have learned from experience that students cannot learn if classes have too many students. Those kinds of classes make for a lot of unhappy students.

Our emphasis is on quality teaching of the technical details of chopper building, engine building, troubleshooting electrical and fuel systems, tuning, sheet metal fitting, and TIG welding.

We do NOT just TELL YOU HOW to build a bike or engine. We SHOW YOU HOW to do each building procedure, and then YOU do it! Our workshop style seminars are detailed and intensive. We take questions anytime during class.

We specialize in teaching the technical specs and the motorcycle mechanics involved in chopper building, engine building, trouble shooting and tuning, as well as all the parts to be installed from a bare frame to the finished bike.

Our goal is to give you personal hands-on wrenching experience and the “WHY” behind everything. This gives you the understanding you need which will in turn give you the CONFIDENCE you need to work through problems you encounter in the future.

We stop after every single procedure for questions and a total clarification of all the issues. We take the “mystique” out of chopper building. You are going to like what we teach and how we teach it!

We also hit on some bike shop details with respect to getting and keeping customers, getting known, running spreadsheets and controlling the paper-chase, insider parts buying strategies, and uncomplicated parts-making ideas that can save you a fortune and make your shop profitable.

Workshop Curriculum

Introductory Discussion – Parts & Bike Types

We discuss styles of bike building and the parts involved in building those bikes: Rigid & softail frames; spoke wheels, billet wheels and tire widths; enclosed and open belt driven primaries; traditional and springer front ends; engine sizes and what to expect in performance, longevity and maintenance; custom wiring and pre-assembled wiring harnesses, etc..

We discuss the difficulty factors with respect to the type of build you will do, and the tools and skills required. We show you how to minimize these difficulties. We also cover cost factors – retail and dealer pricing.

We cover warranty issues and INSIDER FACTS you need to know about the quality of some brands of engines and transmissions BEFORE you buy them for yourself or your customers.

We discuss “what’s it like to ride” details, and pros and cons of various styles…..

……..and the quality of the engines, frames, and many other parts produced by many of the manufacturers in this industry.

We tell you the “war stories” involved with some of the poor quality parts in the aftermarket industry. We discuss which manufacturers produce the good quality stuff, and which manufacturers you may be taking a risk with.

Note: We offer rock-bottom pricing for custom bike parts for our students. We are dealers for Custom Chrome, Bikers Choice, S&S Cycle, Midwest Motorcycle Supply (Ultima products), Wire-Plus, Cycle Electric, and MC Advantages.

TIG Welding

Since Chuck has professional journeyman pipeline and structural welding experience, he can teach you the details you need to understand with many welding situations and applications. He will teach you trade tricks that will save you serious “agony” in out-of- position welding – tricks you will not learn in formal welding school! We have TIG, MIG, stick and plasma arc machines in our shop.

NOTE: We have a TIG welding workshop option available that would add one day of intensive TIG instruction to the seminar. One day of intensive instruction brings most students to an intermediate level of TIG welding expertise. (No exaggeration about that by the way!)

Tool Discussion

We explain what tools you will need for the type of build you will be doing. We compare the different tools you can use to do the same procedures and how you can use cheaper tools in some situations. We also discuss some inexpensive special tools that pro builders have. (Tools that also show others you really know what you are doing!)

Rake & Trail Geometry

We discuss how to compute rake and trail and how to use the numbers to find the fork length and safe trail that your bike will need for safe handling. We discuss what you can expect with various rakes with respect to handling, styling, and in some cases safety.

Torque Specs

The torque requirements of every part is covered as we assemble the bike.

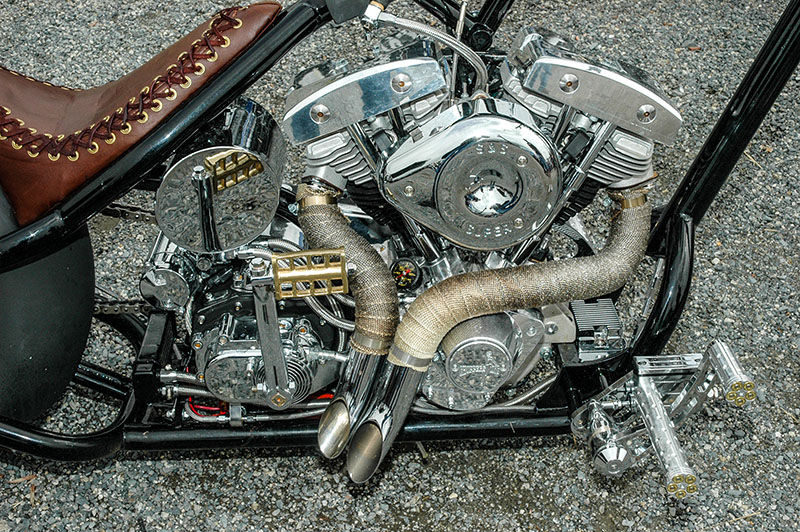

Primary Drive Alignment

We discuss procedures for basic primary drive alignment of the engine and transmission, as well as offset procedures and spacers required when running wide tires for left side drive bikes – engine to primary spacers, offset front belt pulleys, and transmission offsets. Both enclosed and open belt primaries are covered. Students will assemble an open belt primary drive.

Final Drive Alignment

We discuss offset transmission chain sprockets, and rear wheel alignment and spacing issues. We discuss what to do when the rear wheel will not align in the center of the frame. We cover in detail the unique spacing and fit-up required with the “sproter” brake system and deep dish offset rear wheels.

Students assemble a chain driven final drive. We discuss what to do if your rear axle will not go through the hub. It happens often!!

Brake System

Brake installation, shimming, alignment and bleeding is covered, as well as different brake types and differences in mounting positions.

Troubleshooting, Tuning & Basic Motorcycle Mechanics

Guys, you will have a blast learning troubleshooting and tuning.

You will learn a lot of motorcycle mechanics from us and we will build your confidence level and enthusiasm to where you will fear no problems!

We teach you additional motorcycle mechanics so you understand even more about the fuel system, ignition system, charging system, oil system, etc.. You will understand the “big picture” of how motorcycle systems work.

Front End Assembly

We assemble an extended front end and cover 2 different fork stop systems. We discuss how to set up for, and measure for the front and rear wheel spacers that you will need to fabricate or purchase. Students will assemble the triple trees and the front end. We discuss what to do if your front axle will not go through the hub.

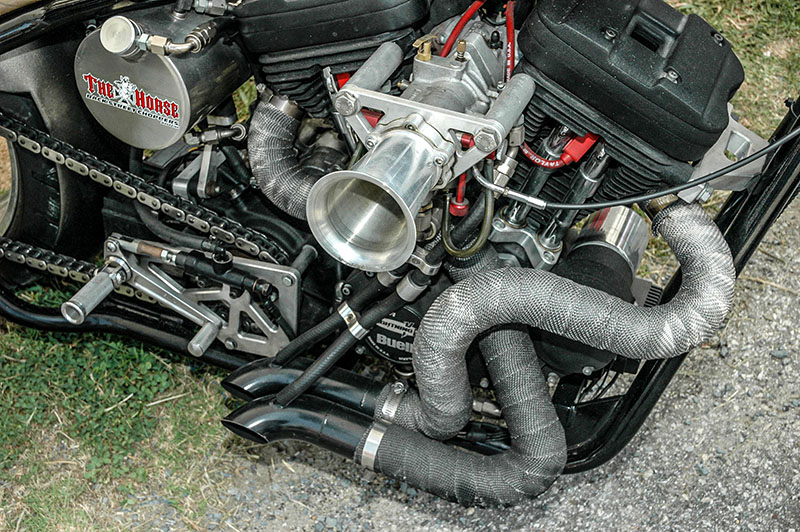

Fuel System Including Gas Tank, Petcocks, Carburetor & Throttle Cables

Next we go over various kinds of gas tanks and how they are attached to the frame in different ways. We also cover different petcock types and set-ups, as well as gas tanks that have different threaded fittings for petcocks.

We cover setting up of an S&S E series carburetor and we completely tear down and rebuild the carb. We also cover how to deal with throttle cables that don’t seem to fit no matter what you do. Students attach the gas tank, petcock, intake manifold, carburetor and fuel line.

Oil Tank, Oil Line Routing & Oil Filter

Oil line routing varies depending on the type of oil tank and brand of engine you are using. This is a critical area that we cover in depth.

Sheet Metal

The measurements, cutting and fitting, and attachment issues with the rear fender, rear fender support bracket, sissy bar, gas tank and oil tank are covered in unusual detail as these areas are a challenge for the first time bike builder who may work alone and have limited experience with TIG welding, metal cutting, grinding and fitting.

Special tools and techniques including plasma arc are covered. Labor time and labor costs are discussed in detail with respect to the complexity of various bike builds.

Electrical Wiring, Ignition, Starting & Charging Systems

The ENTIRE electrical system is explained along with scratch wiring. We also discuss various aftermarket wiring harnesses and wiring systems. Through the frame wiring is covered along with soldering techniques and connectors. We give you schematics for COMPLETE electrical systems – not just the vague wiring schematic that comes from vendors!

Other Final Bike Assembly Details

Clutch adjustment, forward controls, seat pans, painting and powder coating issues are covered. We have a serious discussion of the pros and cons of chrome vs. powder coating vs. polished aluminum as finishes on wheels, brakes and other components.

Hacker Mechanics & Poor Aftermarket Products

There are lots of “learned it on the street” mechanics and builders out there who seem to do some pretty cool stuff. The problems come when you ask some of them technical questions and you find out they really don’t know that much. They are fabricators, not mechanics.

One of the problems is the “I learned it all on the street phenomenon.” The “street” is not always the best place to get good technical information. For example, through the years we have known some street-taught mechanics, and also some Harley mechanics with the “PHD” credentials who were savvy and very knowledgeable. We have had the good fortune to have worked with some of them.

We have known others with the same backgrounds who were “hackers” and “parts changers”. They really had very little technical knowledge. It’s a bit shocking when you run into it – and even a few of them had the “PHD” certification.

It gets even worse when you get “signature products” made by “master builders” – products that are poorly made and are prone to serious problems. And it’s often a bit rampant in the industry. We have some of those products to show you!

You also have manufacturers who are just out to make a buck in the aftermarket with low-ball pricing of their parts. Then, when you ask them technical questions about their parts, you find they can’t answer a single question about their own product! It’s shocking!

Or, there is no technical department and the parts are made in some other country where you will never get to quiz the engineer or product manager. And warranty and service? We discuss these vendors and the war stories in our classes!

In Sum: We Stop to Teach You the Technical Details of Bike Building

We teach you the technical details you need to know instead of just having you blindly bolt up parts. Details like torque specs and what parts do not work well – or, the year when the part was manufactured and what years to avoid. Example: Primary drives. Stock primary drives are not mix and match – and model years differ in quality.

Most of all, we share with you the “war stories” involved with various stages of bike building and how to solve the problems!

Professional Engine Building Workshop Description

Class Procedure: Engine Disassembly

Proper tear-down procedure is demonstrated so that parts are not damaged in the process. An explanation of what every single part does and how it fits is covered during the part-by-part engine disassembly. Students do all tear down and rebuild!

During the teardown, we tell you how Harley part specs have changed over the years and why this knowledge is important to you. All parts are measured with micrometers to acertain proper specifications and to see if wear limits have been reached.

This gives you cutting edge knowledge of Harley engine building that you can ONLY get from us.

Guys, we teach real world “war stories” about how each engine part works, how each part has to be fitted, and how each part should NOT be fitted, as well as what happens in the “real world” on the road – these “war stories” will make you smile!

If you have been a fan of Evo and Shovelhead engines, and have always desired to have a comprehensive knowledge of building these engines, you will probably start laughing at times in this class with the excitement of learning everything you have always wanted to know!

Explained another way, when you begin to realize you are getting 30 years of REAL WORLD knowledge and experience IN ADDITION to the technical details of engine building – well, it kind of feels like you just won the state lottery!

This is exciting insider information and trade secrets that can only be learned from veteran builders who know how to teach.

Example: Sometimes you should do procedures quite differently than what the tech manuals advise. This kind of insight only comes from working on many engine builds.

Discussion of Big Engines

We discuss quality and performance factors of all big engines with real world facts and experiences. From 96″, 113″, 124″ and on up, we discuss little known facts about heat,

cooling, wear, reliability, performance and maintenance. Save yourself some heartache (and money) and learn the good, the bad and the ugly about various big engine displacements and high compression models.

We have lots of real world experience with big engines – positive and negative experiences – and we discuss important little known facts that aftermarket engine manufacturers really don’t want you to know about the quality and performance of their big engines. We also discuss these engines brand by brand.

We cover horsepower and torque facts in a way that makes sense and cuts through all the hype. High performance modifications and requirements are covered.

Class Procedure: Engine Balancing

Connecting rods, rod bearings, pistons & wrist pins are balanced on a scale and weight differences are adjusted in the flywheel in order to get balanced reciprocating and rotating motion.

Class Procedure: Flywheel Truing

Even more important than engine balancing is flywheel truing. Flywheels are placed in a truing stand, run out is measured, and the flywheels are trued in response to the run out measurements. This is the biggest factor in reducing V-twin engine vibration. Connecting rod side play is checked.

Class Procedure: Engine Assembly

Proper building procedure is demonstrated part by part until a completed engine is built and fired up. An explanation of what every single part does and how it fits is covered.

Again, all assembly procedures and parts are accompanied by colorful “war stories” of what happens when things are done wrong. This is where “REAL WORLD” learning comes in! This seminar is not a dry “how to” exercise that makes you look forward to the next coffee break

Engine Building Tools

Proper use of all special tools used in engine building and where to get these tools is covered. Real world experience of how NOT to use these tools is also covered. How to read micrometers is covered in detail.

Cylinder Measuring & Boring

Think you can just grab a bore gauge, take measurements, and “go to town”? Think again. There are surprising facts and procedures you need to know about piston to cylinder wall clearance. Proper cylinder measuring and boring is demonstrated in class.

Class Lecture: Engine Troubleshooting

- Correct engine start-up procedure including troubleshooting before engine fire up

- Engine tuning after fire-up

- Engine troubleshooting after fire-up

- Electrical system testing

Oil Lines, Oil Routing Through the Engine & Oil Scavenging & Pressure Differences Over The Years

Get this wrong and you are going to blow oil all over your garage wall or your driveway. We teach you how to recognize the issues on multiple engines and get it right the first time.

Other Technical Engine Building Procedures Covered in The Workshop Are:

- Proper torque procedure and all torque specs.

- Degreeing the Cam and ignition timing

- Cam cards of aftermarket camshafts covered

- Measuring camshaft endplay

- Measuring camshaft and pinion gear mesh and choosing proper camshaft size

- Setting cam and breather timing

- High performance cams and their particular requirements are discussed

- Crankshaft endplay

- Piston to rod bushing clearance

- Piston design, theory, and development over the years.

- Wrist pin (rod) bushing removal, install, and reaming of new bushing

- Fitting Piston rings

- Cylinder to piston fitting

- Cylinder head assembly and disassembly

- Valve stem clearance and wear limits

- Valve guide measuring, installation & replacement using heat and cold

- Valve seal replacement

- Valve seat cutting procedures and tools

- Solid and hydraulic lifter differences

- Solid and adjustable pushrod differences

- How to set adjustable pushrods

- Measuring preload

- Pinion shaft, bearing & race tolerances and service wear limits

- Rocker arm bushing measuring and installation/replacement

- Cylinder stud removal and replacement

- Breather system – how it works and has evolved over the years.

- A complete engine building tool list is provided with part numbers

Registration, scheduling, and pricing details for our hands-on workshops.

Sitelinks

Our Workshops

Do you work better with "hands-on" training. Click here to learn more about how to build a chopper and Harley repair classes.

Contact

Redline Chopper School

233 Illinois Avenue

Westerville, Ohio 43081

614-882-5975

fox55@midohio.twcbc.com

Designed & Powered by SOCIALFIRM